Manufacturing

We harness our team’s boundless creativity to imagine your workspaces, workstations and products. And when it comes time to implement them, our team really gets down to work.

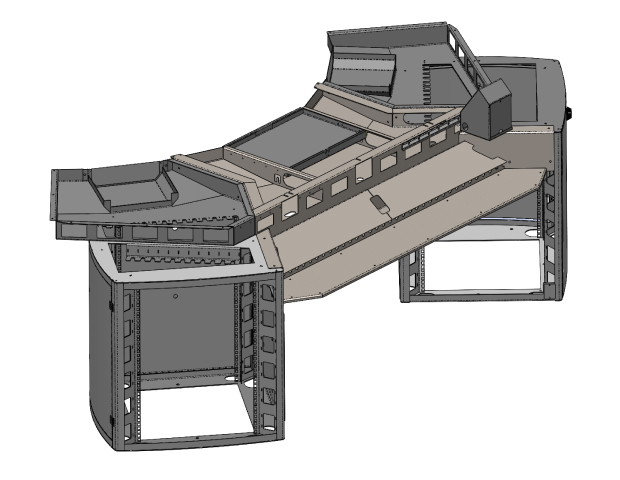

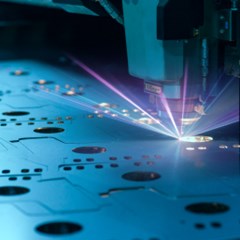

We work with reliable and efficient partners to produce consoles and a whole range of other items, individually or in production runs. Our partners are experts in working with sheet metal, wood, polyester, paint, injection moulds, and 3D printers. Thanks to our detailed digital production files, you can rest assured that your projects will benefit fully from their expertise.

The challenge: go from concept to finished product while meeting deadlines

After conducting a detailed study to ascertain the most suitable technologies, we carry out a constructive analysis, which allows us to generate the production files necessary for our manufacturing subcontractors. Then the prototyping and optimisation phase takes place, followed by the production phase.

The manufacturing process is constantly monitored to ensure it follows the standardised designs and implements the specific solutions your project requires.

What you get

- Qualified subcontractors

- Our quality-control procedure

- Our integration work

- Transport and on-site installation if required

- Quality control at every step during production