Develop and manufacture a modular train simulator concept for Transurb

The assignment consisted in producing and implementing, on the basis of a concept provided by Transurb, a prototype followed by a series of six simulation consoles for three different locomotives, destined for Morocco, according to strict specifications and a strict budget.

The client wanted Symbio to take into account the aesthetics of the consoles and their inclusion in the Transurb range. The consoles also had to be easy to move and reconfigurable, and offer easy access to technical equipment.

The challenges

In accepting the assignment, Symbio took on two major challenges. First there was the integration of the simulation equipment from three types of locomotive into a single console. Symbio had to develop technical solutions that would allow the sets of equipment to be interchanged, so that they could be switched easily from one locomotive to another.

Second was to combine metal, polyester and compact laminate. The shape of the console needed to be reminiscent of the railway environment in its lines, while keeping the look and the finish of a cockpit. Symbio therefore selected the most suitable materials for each of these functions. The technical body and the outer hull were made of sheet metal for the sake of strength and technical support, the interior of the cockpit was made of polyester, which has a nice finish, and the top of the drawer was finished in compact laminate, which has a good feel and is resistant to scratching.

The results

The first step in this assignment was to make sound choices in terms of the technologies and materials for the structure of the console.

The second was to develop a solution that would make it possible to train a future driver on three types of locomotive without modifying the structure. Symbio developed plug-and-play drawers, and considered their connectivity, safety locks, and the best way to make them slide. It was then a matter of integrating the hardware and of optimising maintenance.

The third step was to develop simple and efficient solutions for handling and moving the consoles on castor wheels.

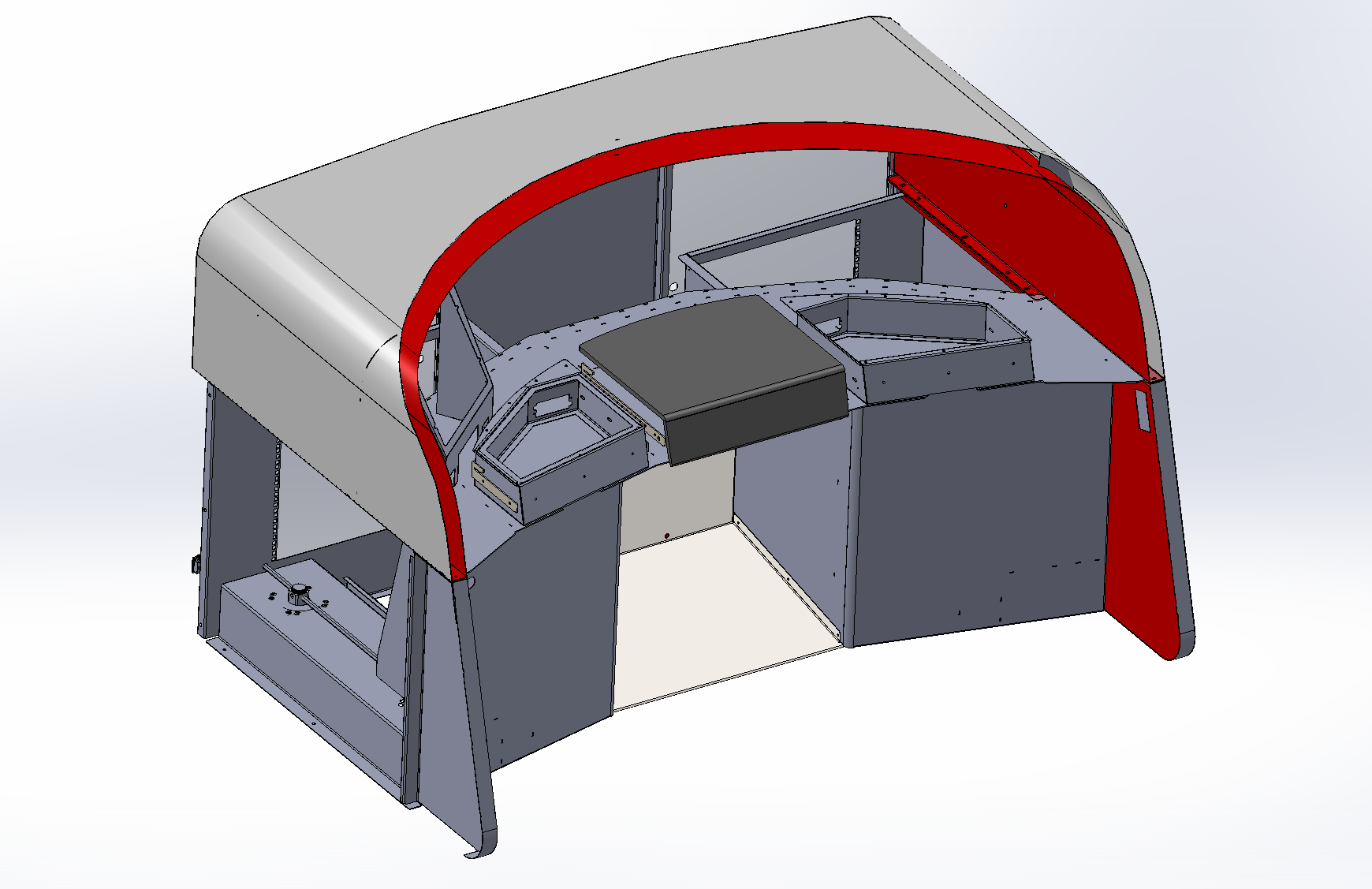

Production file for the proposed solution

Once the project was approved, the Symbio team created the production files, which can be used directly by its various subcontractors, who produced the various components that comprise the simulator.

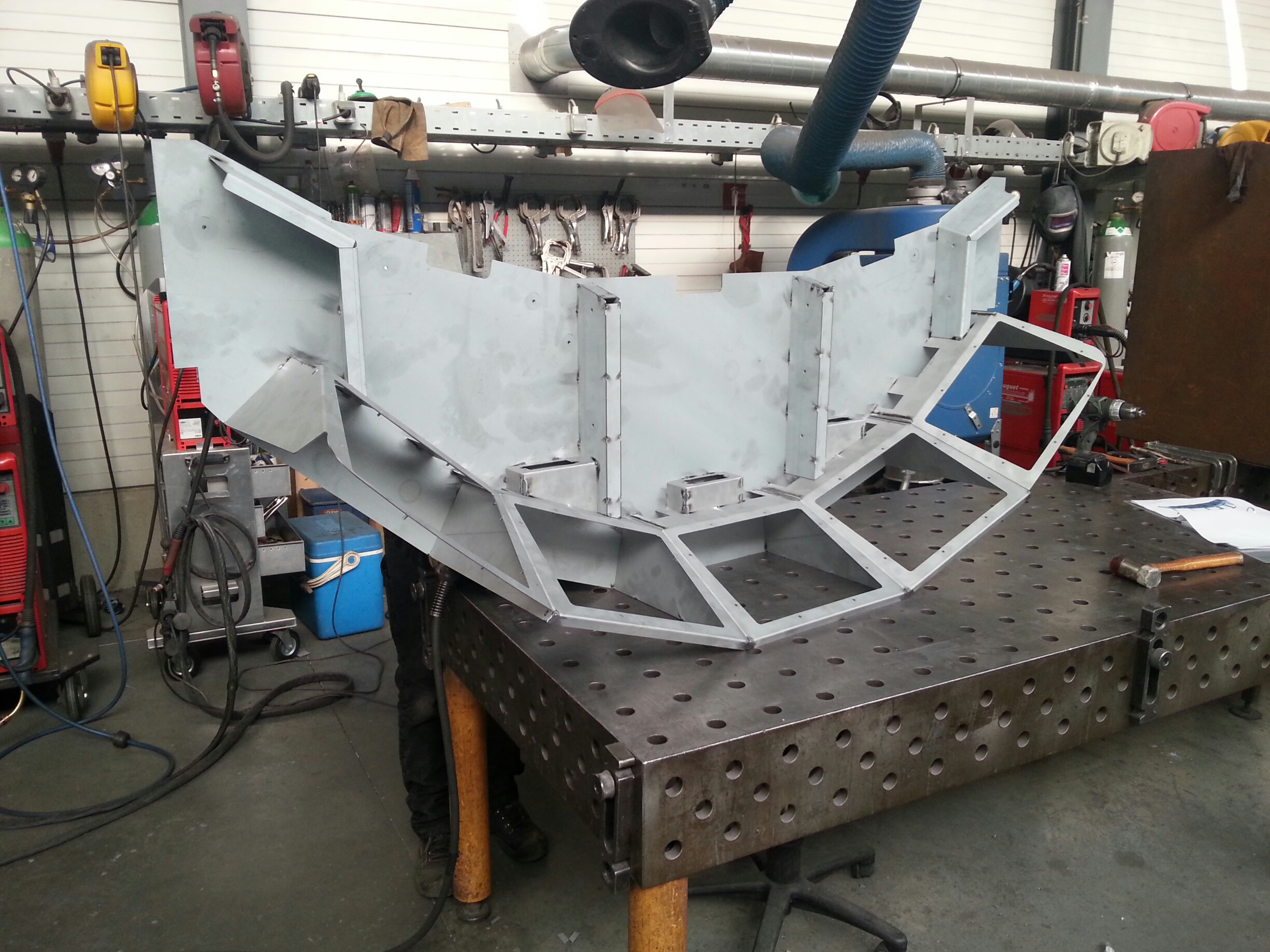

Support for the worktop at the welding station

The cockpit being prepared in the polyester workshop

However, Symbio was responsible for the final assembly of the simulator structures before the simulation equipment is delivered.

Console being assembled at Transurb

Once the structure was finalised, Transurb was responsible for the integration of the hardware and software simulation equipment. After a final internal test, the simulators were installed on site in Morocco.

Final result: a close-up of the equipment

Final result

Transurb

Transurb is a Belgian limited liability company that has been offering tailor-made solutions in railway and urban transport for more than 15 years. By combining internal resources and pooling the experience and resources of their shareholders and partners, the company offers best-in-class solutions and training for railway and urban transport the world over.

Share this: