Symbio's team designs Belgocontrol future en-route control room

The project has been performed as a subcontractor of Tractebel Engineering. Symbio was tasked to design the work consoles and their spatial organization (layout) in the room, produce a mock-up and a prototype of the main console type, to be used as proofs of concept, and then finalize and validate that design. This was to be followed by the production of specifications allowing a call for tender for the manufacture of the consoles.

The study was carried out in a cooperative manner with the end users through a dedicated workgroup provided by Belgocontrol.

The room designed by Symbio during this project was built by Thales in 2008, with Symbio manufacturing all of the furniture it contains.

The challenges

The main challenges for Symbio were about

- The design of the workstations themselves, optimizing the interaction between users and equipment

- The integration of all the workstations in the available architectural space, optimizing the interactions and information flows between workstations and between operational sectors

- The uncertainty concerning the presence or not of military controllers in charge of dedicated airspaces and receiving dedicated operational stations in the room, with an impact on the final layout

- Taking into account the diversity of the points of view within the working group, made up of about fifteen controllers with different levels of expertise and specialties

The results

The study was carried out in two successive but interdependent phases: the design of the consoles or workstations and the design of the console layout in the operating room.

Console Design

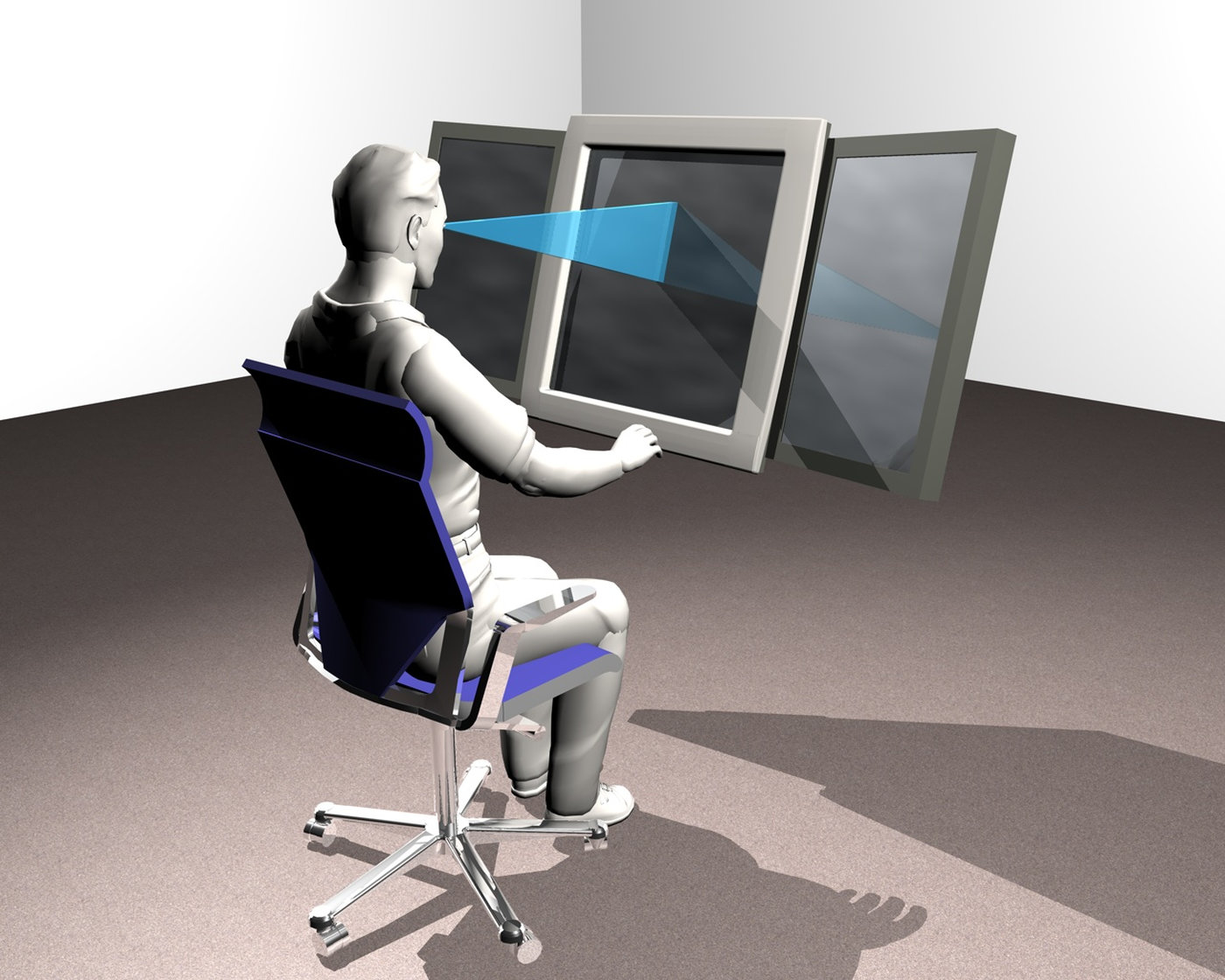

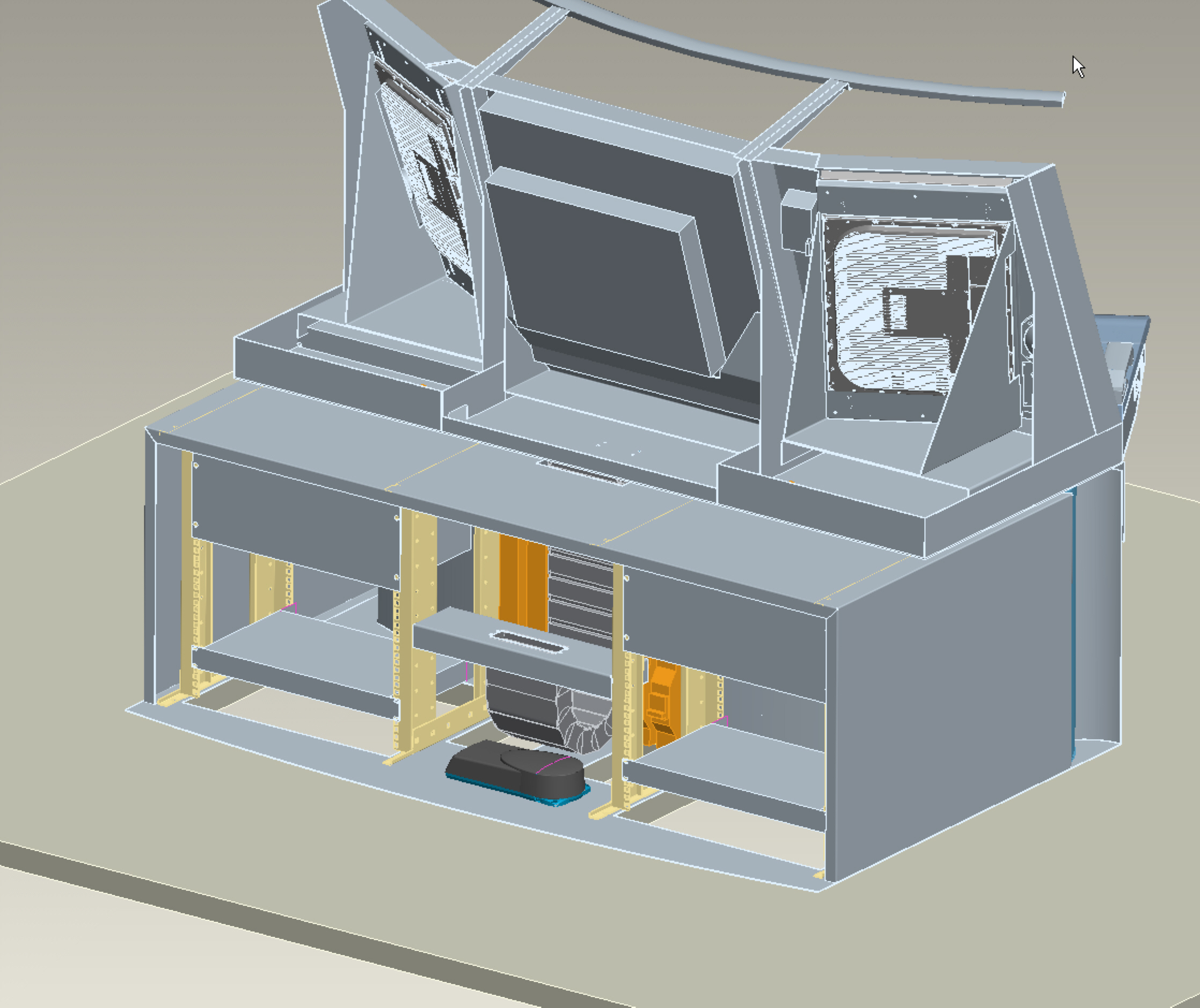

The design of the work console was aimed at fully satisfying all operational needs and current ergonomic standards. Symbio's approach is based on the optimization of man-machine interaction, ignoring the furniture itself, at least at the beginning of the design process. We optimized the position of the console's displays and only then designed the supporting structures for these displays.

|

|

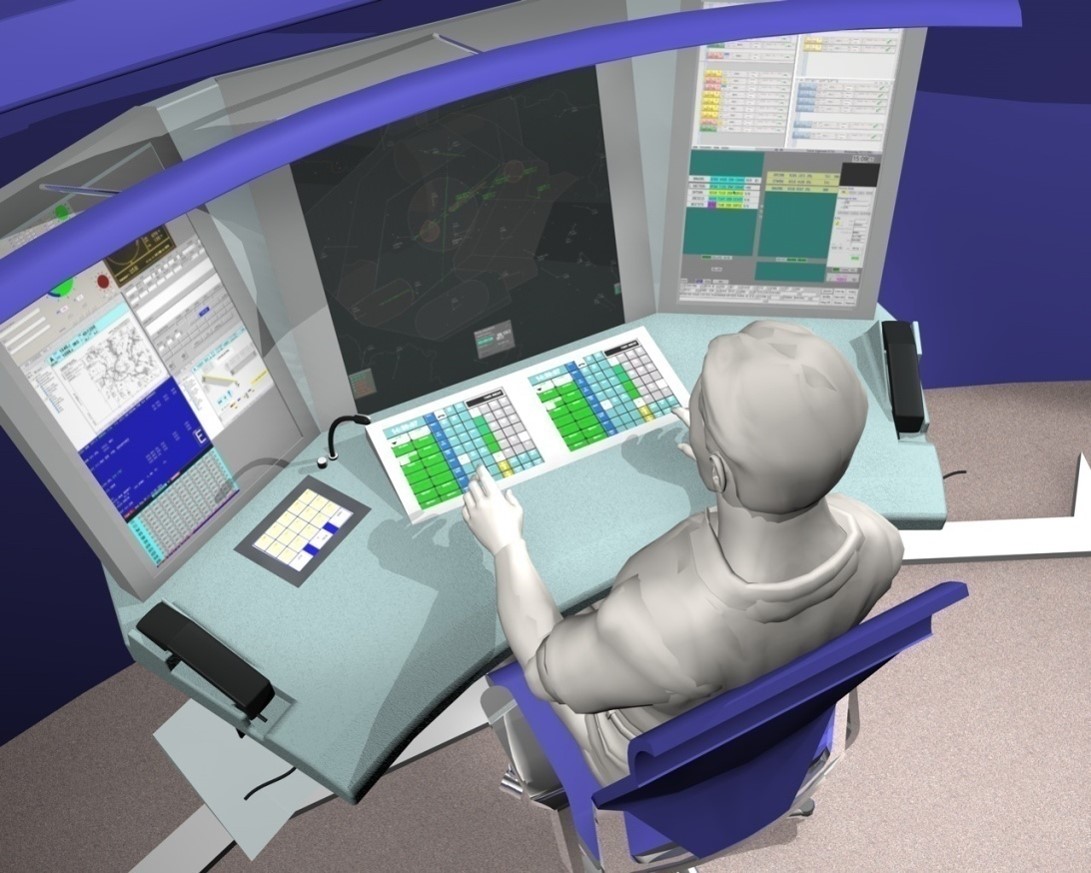

Once these elements of human-machine interaction were optimized and validated, we integrated the other equipment with which the user interacts on the console, focusing again on the optimization of interactions, without over-specifying the hardware components of the furniture.

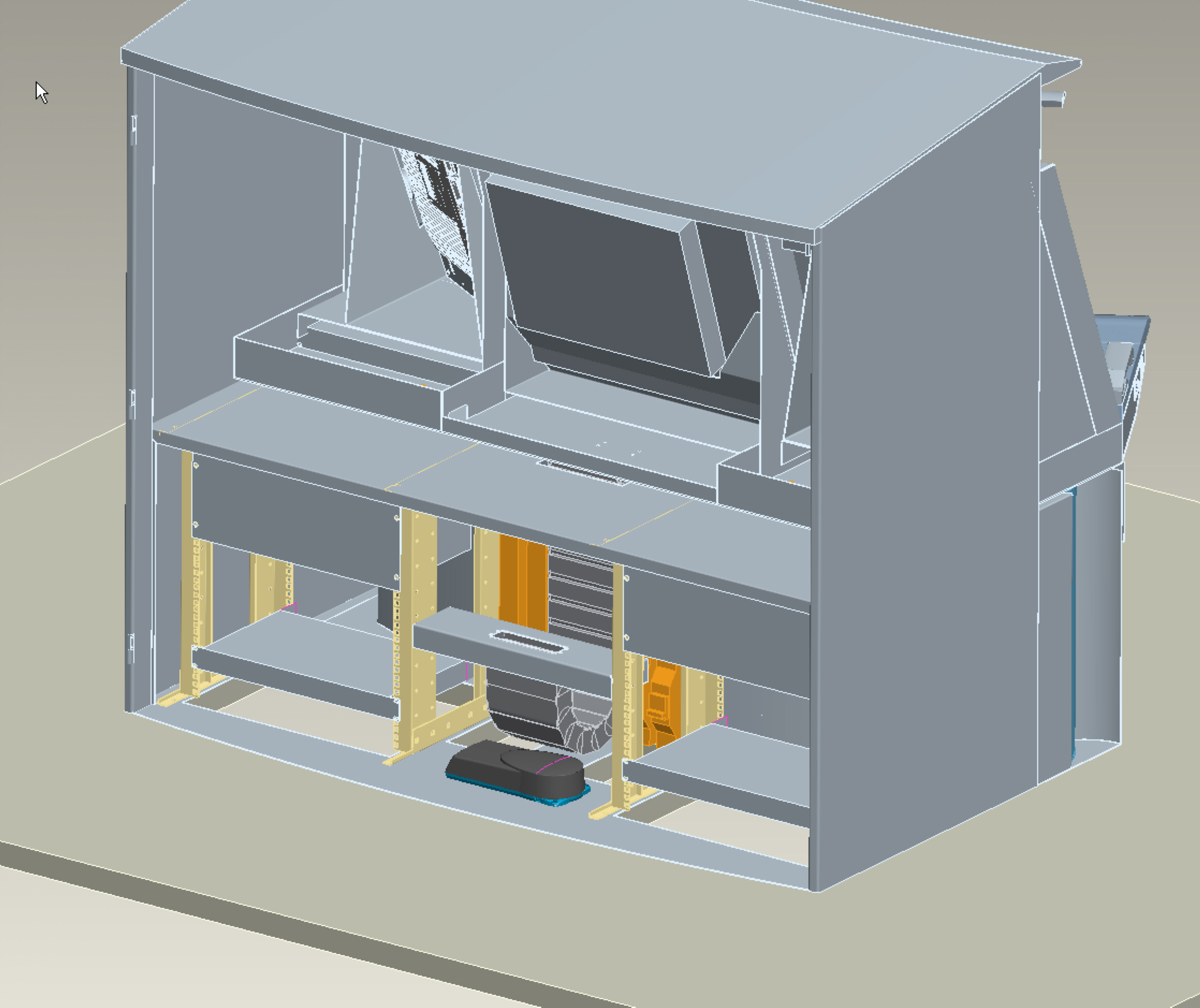

The physical elements of the workstation are then added, such as the furniture body or a protective visor to prevent the effects of overhead lighting on the workstation displays.

And the complete bodywork, including all the equipment, is then added.

The furniture concept was then tested with users, using a simplified mock-up with the screen and equipment layouts predefined during the study.

|

|

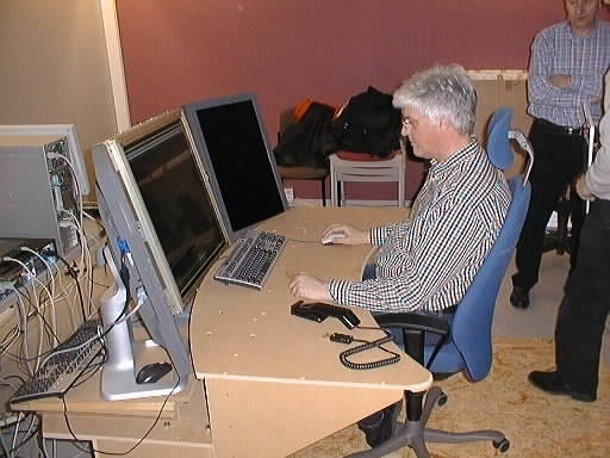

Once the basic concepts were confirmed and refined, Symbio proceeded with the constructive study of the furniture, with a view to producing a realistic prototype.

|

|

|

The prototype was used for evaluation by the end users, through the execution of 20 tasks typically performed at the workstation, with measurement of execution time, and a subjective questionnaire addressed to all users. The furniture was then refined and defined in its final version. A specification for the mass production of the furniture was then written.

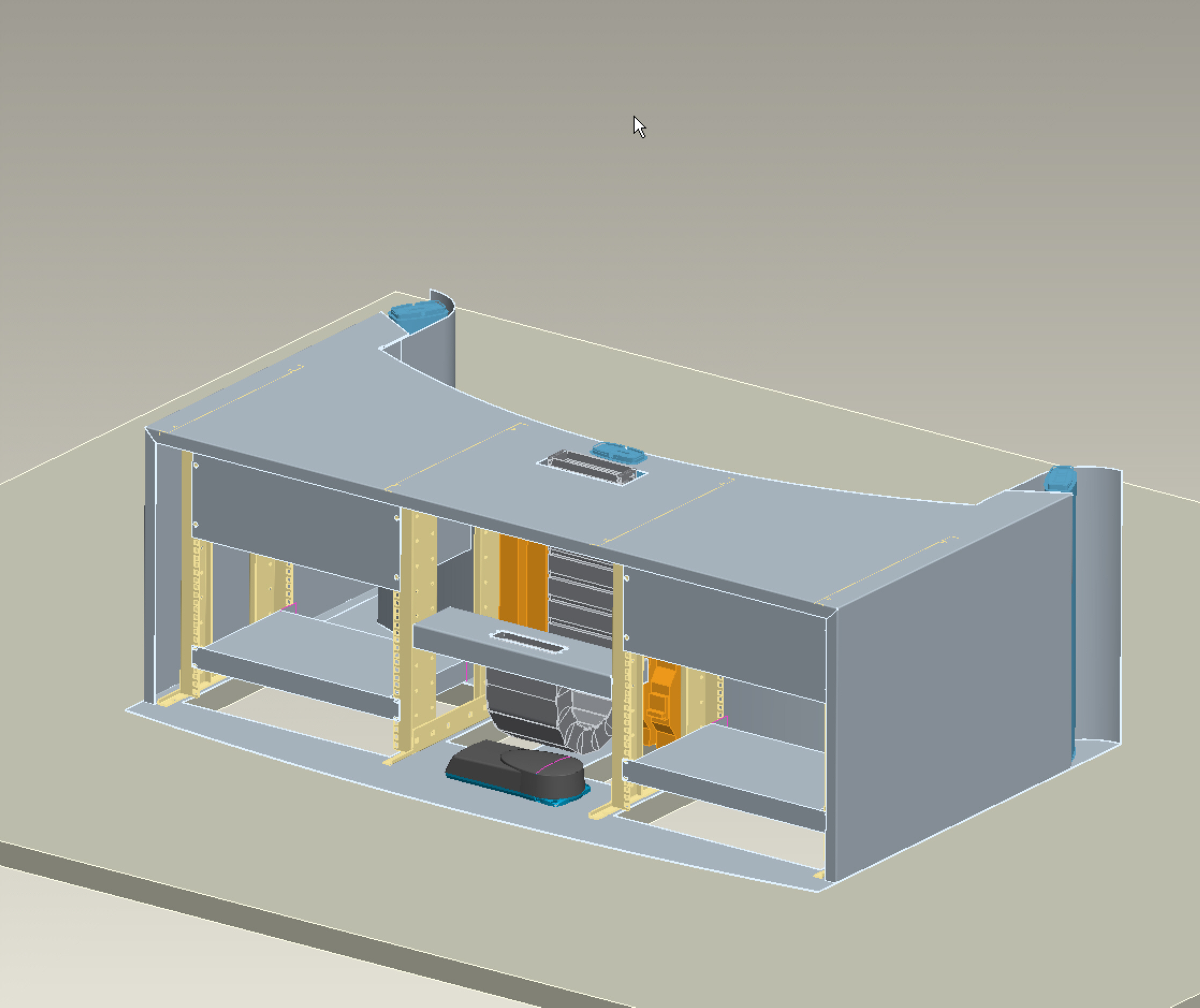

Layout design

Once the furniture was defined, we worked with the working group to design the layout of the consoles in the future operational room.

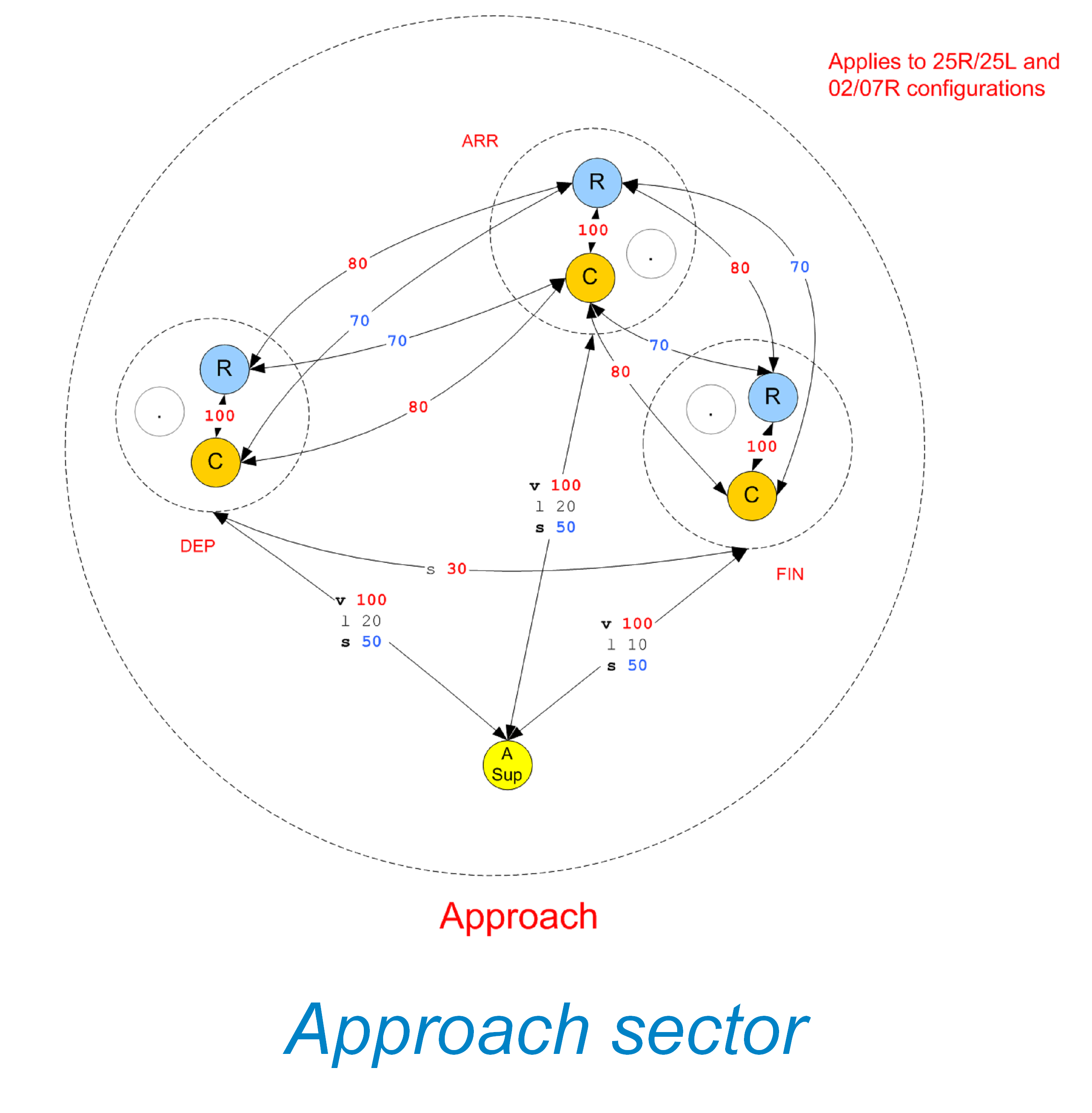

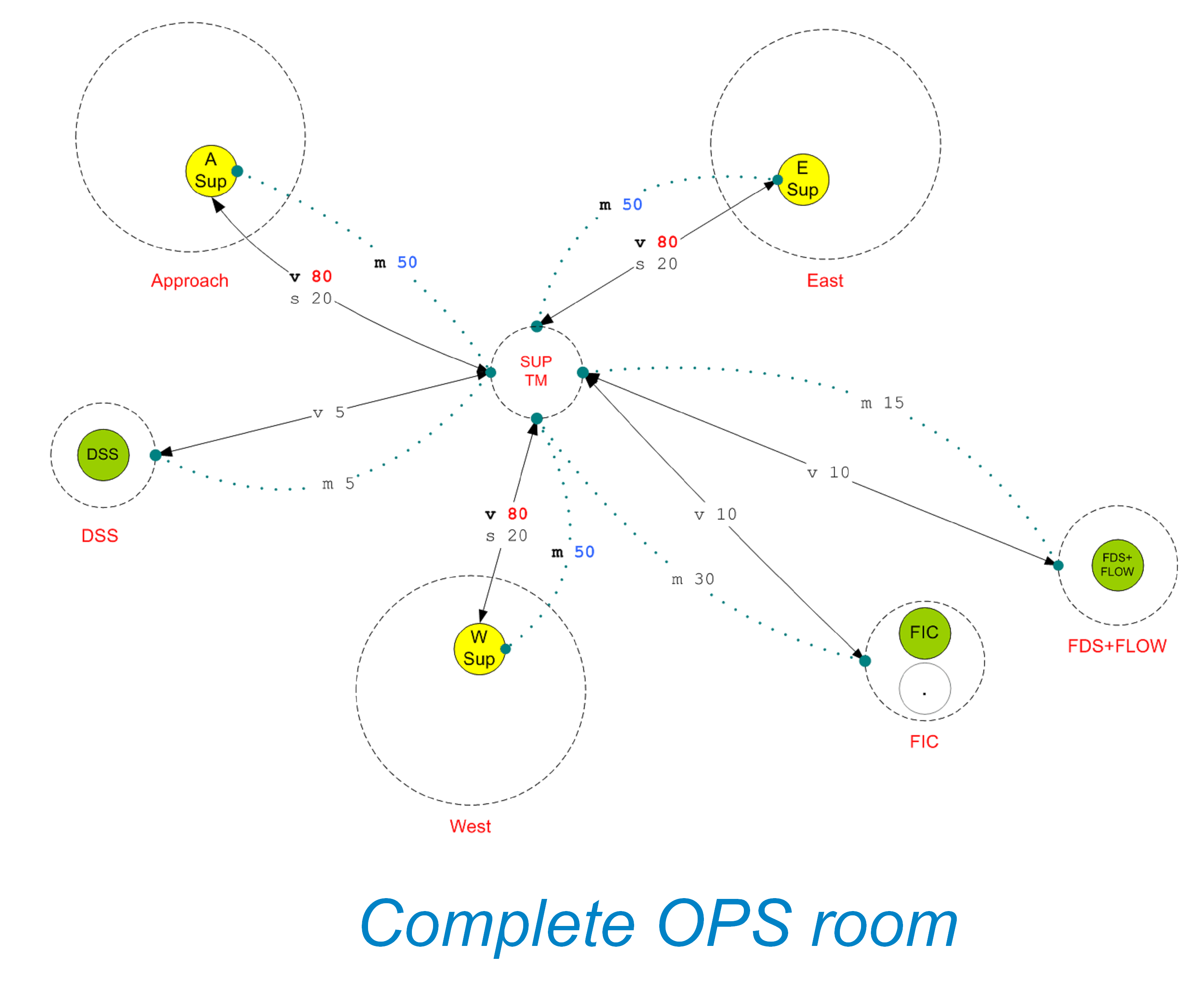

The first step of the layout design was the study of the interactions and information transfers that should exist between the work positions and between the different operational sectors in the room.

Below is the complete diagram for the entire room as well as a more detailed study of the interactions within the approach control sector.

|

|

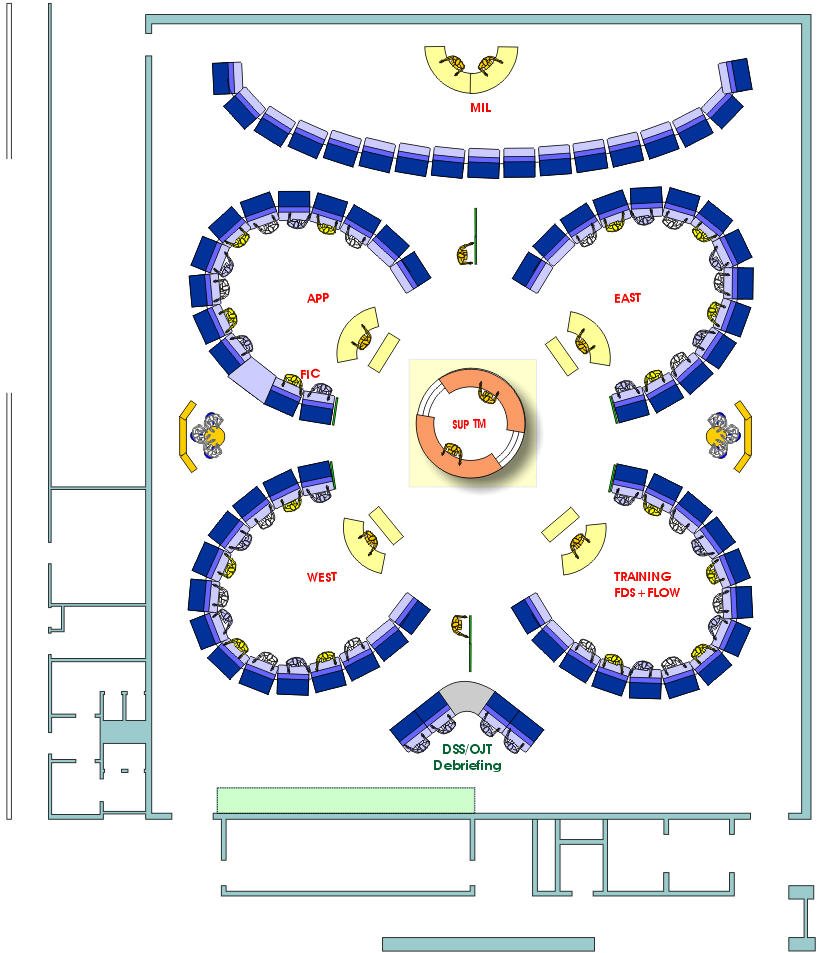

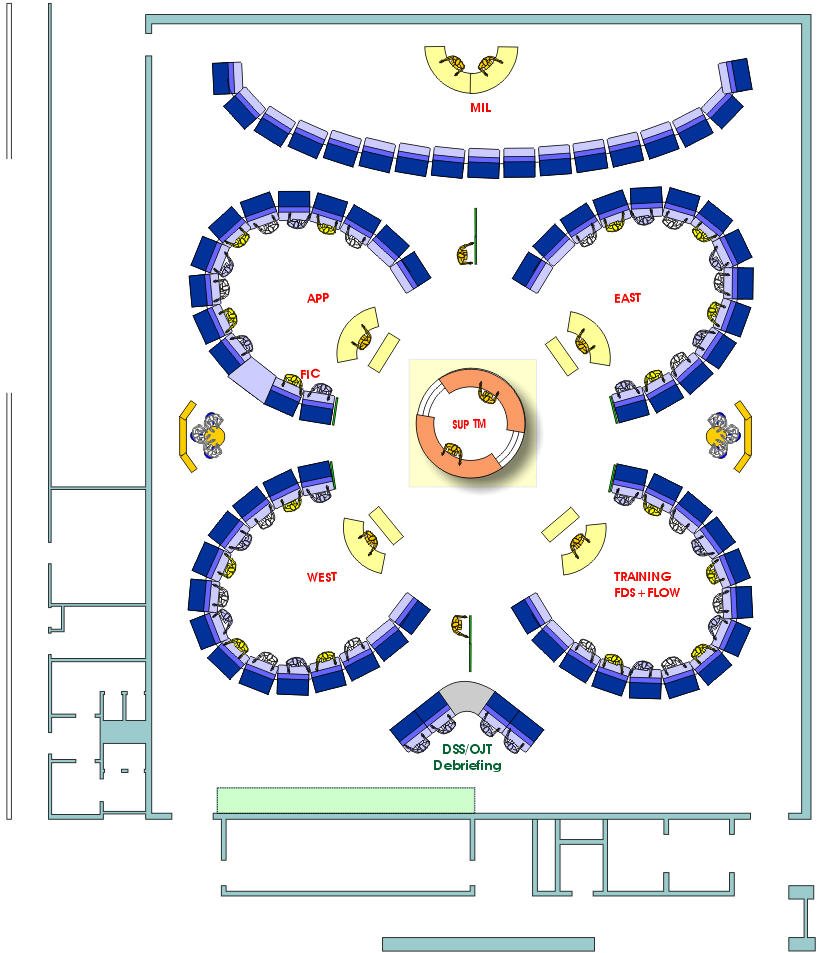

On this basis, different layouts were produced by the working group led by Symbio. Two main options have emerged.

|

|

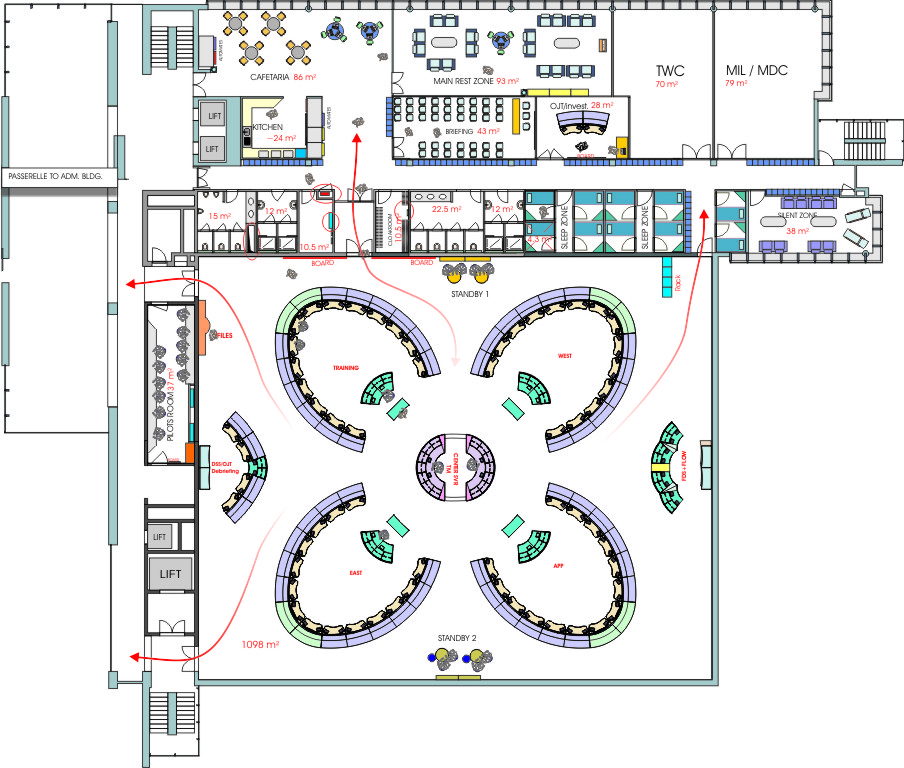

The first layout was chosen and a more complete and refined version including the integration and interactions with the rest of the building was produced.

Various 3D renderings of the room and the working positions were produced, using of course the still rather limited technology of the time (early 2000s).

|

|

The real workstations were produced in 2008 by Symbio on behalf of Thales, the company that won the contract to build the room, both in terms of hardware and software.

|

About Belgocontrol

Belgocontrol is the Belgian air navigation and traffic service provider for the civil airspace for which the Belgian State is responsible. It was created in 1998.

Share this: